TIG Welding & Micro Welding Services

ABR have offered a TIG and micro welding service to UK industry for forty years.

Large build ups of weld can be achieved relatively quickly. As such, TIG welding provides a cost efficient welding solution.

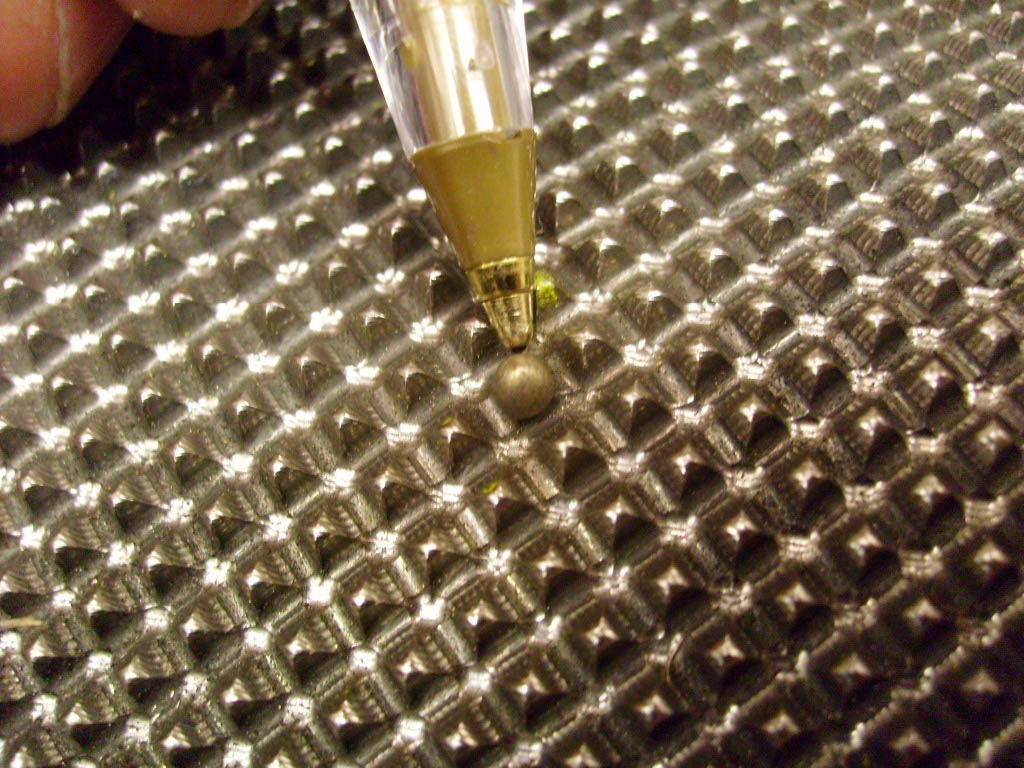

In order to achieve the optimal post machined finish, TIG welding witness lines or heat sinks can be removed with laser welding. This is often desirable on polished or textured mould faces, cylinder block fire faces, sealing faces and various other critical areas.

Micro welding, a process pioneered by ABR in the 1980’s, enables the precise placement of very small amounts of TIG weld. This is particularly beneficial to minimising post weld rework.

Combined with the correct filler wire, the TIG welding process can produce a very hard and durable weld. As such, ABR’s TIG and micro welding service is often favoured by the pressure die-casting and press tool industries.

With its higher level of penetration, TIG welding is also well suited to the repair of cracks, leaks and sealing of water channels.

ABR also have high power AC equipment for the TIG welding of aluminium.