Laser Welding & Cladding Services

ABR has over twenty years’ experience in laser welding for UK industry.

Continual investment in the latest laser technology enables ABR to offer a rapid turnaround service. Seven different laser systems with a handling capacity up to 8 ton ensures most undertakings are completed on a same day or next day basis. A weld whilst you wait service is available.

The advantages of laser welding are:

- Minimal heat input to the workpiece resulting in a narrow HAZ (heat affected zone). This allows ABR to weld delicate tools and components without distortion.

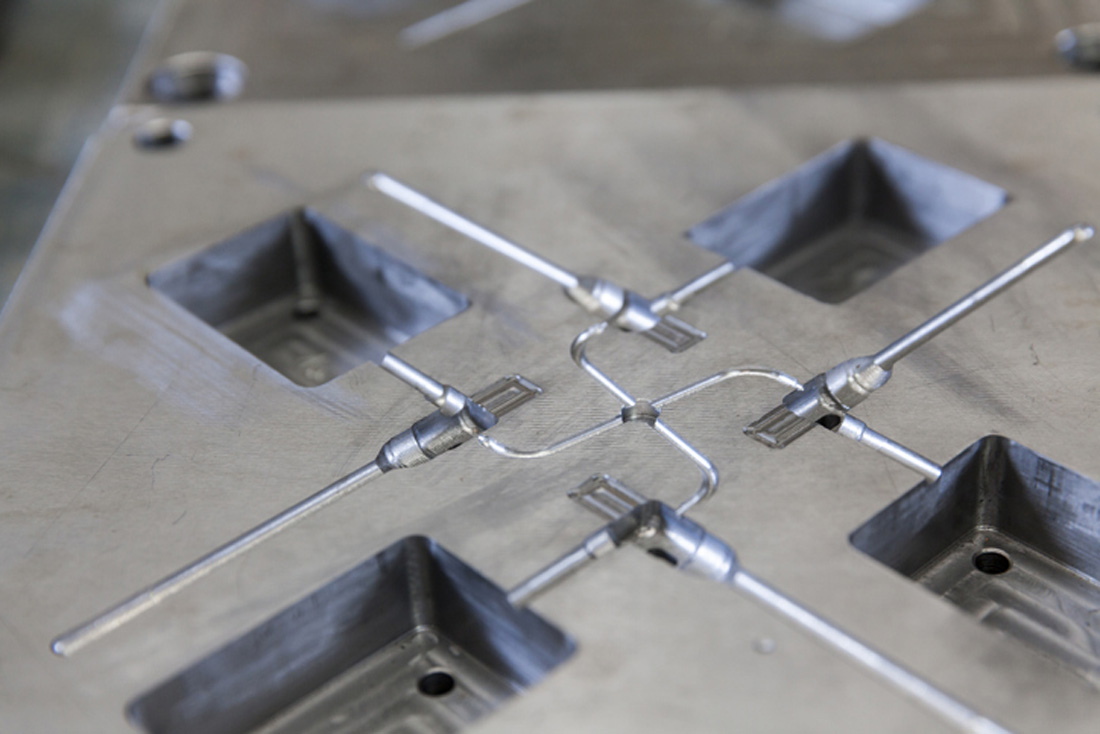

- Ultra-precise weld placement, achieved using powerful magnified viewing optics. Particularly beneficial when welding on plastic mould tools where weld encroaching on to surrounding area’s such as a textured mould face can create costly rework.

- Ability to place weld in areas other welding techniques cannot reach. ABR can manipulate the profile of the laser beam in order to weld inside small slots and holes 1 to 2mm wide. ABR also has specialist equipment which allows us to weld inside deep mould cavities and internal diameters. Our largest laser system has a reach of 2.5 meters allowing us to access area’s other laser systems cannot reach. ABR are experts in accessing difficult to reach weld areas so please contact us to discuss what might be possible.

- Precise welding of aluminium and copper alloys. Very little heat input compared to conventional welding processes.

- Laser welding can be used to remove pitting, witness lines and heat sinks caused by other welding processes.